Have you experienced the stress of a complex, high-ticket customer-supplier relationship going awry?

The problem often occurs when there’s a mismatch between the customer’s expectations and what the supplier has available and can actually deliver — particularly if it’s an internal supplier.

How Do Things Go So Wrong on Both Sides?

Many sales reps can only promote their offerings in very general, benefit-laden terms. They may not be aware of what their typical customer’s experience is, or how challenging project implementation can be. They usually know how to give a conceptual description of the product or service’s features, but may not be able to explain concretely how they work.

Sometimes customers get lucky and the services provided are fully satisfactory. But too frequently customers are only “satisfied enough” even after a chain of revisions or add-ons. Worse, they may have to struggle to squeeze out enough value to counteract the damage of a botched-up service delivery.

Missed Signals Lead to Misunderstandings

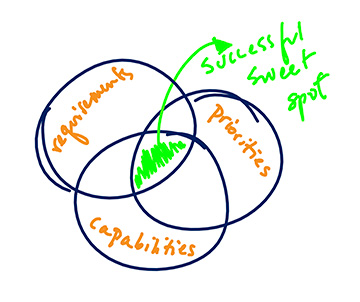

Customers and suppliers coexist in a Venn diagram of requirements, priorities, and capabilities — some of which are identified only by one side, aren’t articulated upfront, or remain unknown and imperceptible to both.

Customers and suppliers coexist in a Venn diagram of requirements, priorities, and capabilities — some of which are identified only by one side, aren’t articulated upfront, or remain unknown and imperceptible to both.

Customers don’t always have the technical acumen or experience to describe — or clarify — their requirements. Even knowledgeable customer representatives rarely understand all of their stakeholders’ concerns, and the stakeholders themselves may not realize that their priorities for features, timing, etc., and their beliefs about the supplier’s capabilities will ultimately determine the success of the project.

Meanwhile, many suppliers position their product or service as the answer to every possible need without fully assessing the customer’s internal workings, history, or vision for the future. Worse, they may not appreciate just how much the customer believes is included in the package.

The supplier’s capability to execute — both technically and in the relationship — may also vary. Plus, salespeople often have divergent definitions of terms, just as smart people differ about what “ease-of-use” means, or what comprises branding. What ought to be a partnership may be just another job that has to fit the supplier’s staff resources and protocols: Plug-and-play and walk away.

How Can Customers Get Closer to What They Want?

As in any relationship, this is a give-and-take between imperfect parties, and both sides don’t know what they don’t know. So, along with digging deep to understand their own needs, and being excruciatingly forthcoming with suppliers, customers should:

- Verify that the supplier has a significant track record. Examine that track record for evidence that the current staff has sufficient skill, understanding, and the “secret sauce” of relationship to mix it all together. Don’t serve as a beta site unless experimentation is an explicit goal for you.

- Check references rigorously to learn what aspects of the supplier’s process and delivery have gone awry for even its most satisfied clients. The trick is to find situations similar enough that those clients’ comments are relevant and meaningful.

- Allocate more of everything — money, time, creative thinking, and patience — to the project, since plans and reality rarely match perfectly. Sometimes you can’t explain what you mean until you see it in action; other times, you won’t truly know what you want until you’re presented with something that’s not “it.”

What’s the Supplier’s Responsibility?

The supplier needs to deliver what’s promised — after doing the probing and analysis to understand what that promise means to the customer — and without merely taking the customer’s descriptions and desires at face value. It’s the supplier’s job to invest in learning enough about the customer’s company and situation to be confident that their offering is actually a good fit.

Onward and upward,

LK